1 February 2017

What is permeation, really?

Permeation is the process where hydrocarbon molecules from the fuel escapes through the pipe wall to the outside. This happens in all unlined plastic piping and is the reason why unlined piping is no longer in use - at least not for product lines.

Early, non-lined fuel piping, showed clean signs of permeation like "sweating", being oily to the touch and looking "clean" after excavation, since dirt and mud would not stick to the pipe. Since those days, piping standards have emerged setting more or less strict limits on allowed permeation.

Now, let us take a look at some more or less shocking revelations related to fuel permeation and standards.

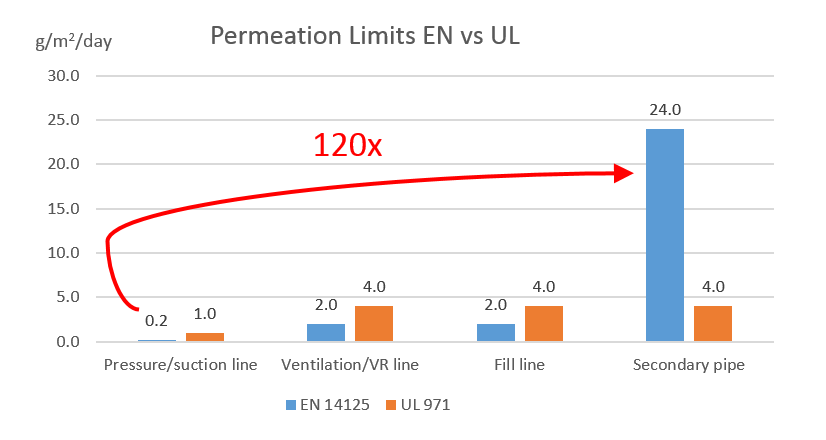

2. Secondary Pipes may Permeate 120 times more than Primary Pipes

The EN standard allows the outer pipe in double wall piping to permeate

120 times as much as the primary pipe: 24.0 g/m

2/day instead of 0.2 g/m

2/day.

The EN permeation level of 24.0 g/m

2/day quite conveniently corresponds to that of an unlined PE pipe, thus allowing manufacturers to supply cheaper unlined pipes for secondary containment if they wish.

The UL standard, on the other hand, quite reasonably maintains the same level for secondary containment as for other pipes not expected to hold fuel for any long periods of time.

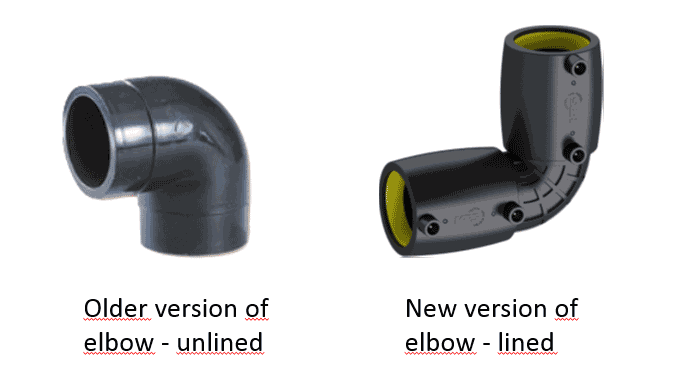

3. Too Many Piping Components Completely Lack Any Permeation Protection Whatsoever

Even though important components like tees, elbows, welding sockets, reducers and transition fittings are included in the standards there are no limits at ALL on how much these components are allowed to permeate.

Piping suppliers have chosen to either provide components with lining/permeation protection anyway - or to go for the absolute minimum, which is unlined PE components. It is up to those who buy or specify piping to look for the differences.

Unlined components can be expected to permeate approximately 24 g/m

2/day. If you have a site with 4 dispensers and 4 different fuel grades there will be 16 tees or elbows under dispensers only. One may find it reasonable that these should not be allowed to permeate freely.

4. Some Decision Makers Actually Value Permeation Performance

Surprising to some, not all decision makers look only at the price tag and ease of installation. Product quality is key to many companies and some also care about environmental safety to such a degree that they take the trouble of finding out how different piping systems and components perform when it comes to permeation prevention.

Constructing and running filling stations is a serious business. Fuels are great for keeping cars and trucks running, but not so great in contact with humans and the environment. We owe it to each other to pay attention to detail and to choose the best available solutions. A growing number of decision makers actually do so.

5. Germany Decided that Zero (0) Permeation is the Only Acceptable Standard

Germany has called for an exception to the EN 14125 standard that is otherwise mandatory for all countries within the EU. Instead they are keeping their own standard that require zero permeation: 0.0 g/m

2/day. Up until the time when the technical development of plastic piping could catch up to these requirements in 2012, Germany stuck 100% to steel or plastic-covered steel.

The German testing methods to verify zero permeation are, as can be expected, very precise. Samples are put in an airtight chamber with equipment that is measuring the number of hydrocarbon molecules that escape from the pipe through permeation. This can be compared to the more common method of measuring the weight loss of a closed-up, fuel-filled pipe sample over a defined period of time.