7 December 2017

Sometimes repairs or modifications to the piping system need to be done. This can be years or decades after the initial installation. Sometimes mistakes are made during the initial installation that will prompt a correction or repair.

Regardless of the reason, there are a few product that can really come in handy whenever repair or modifications are being done.

1. The repair socket

The repair socket is used whenever there is need to replace a socket, either because it was found to be leaking or if there was a power outage in the middle of welding. Shit happens, we just need to be able to fix it.

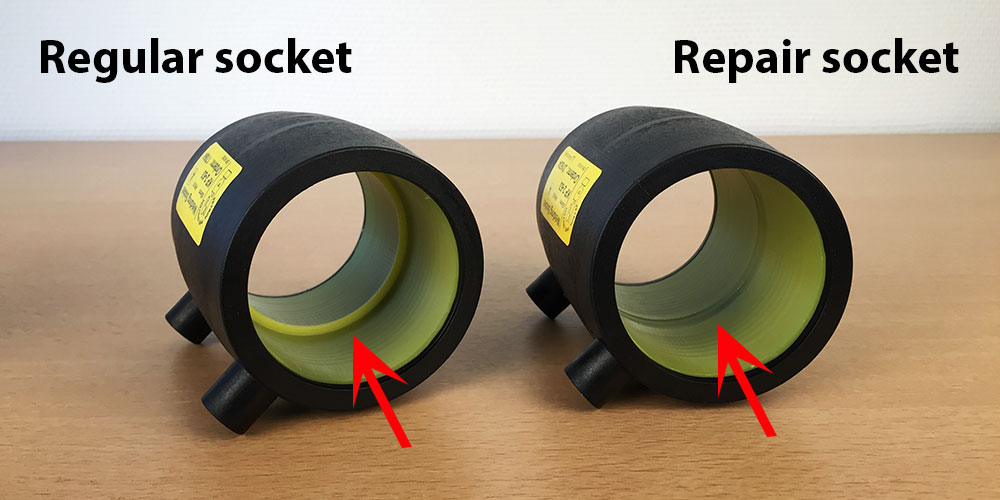

The repair socket looks like any welding socket on the outside. But in this case it is the inside that matters. The repair socket lacks the pipe stop you will find in regular sockets.

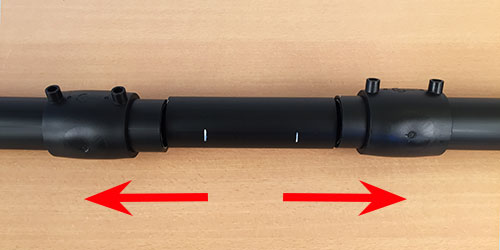

Once you have cut out the faulty welding socket, measure up a piece of pipe that will fill the gap. (Make sure the cuts are nice and square first!)

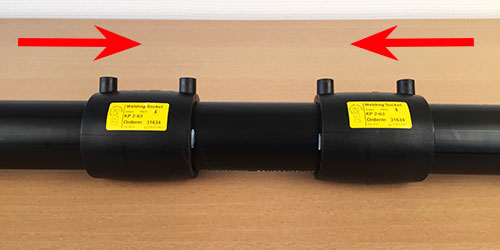

With regular sockets you would need to free long lengths of pipe to be able to fit everything together, but not with the repair socket. Since there are no pipe stops in it, it will slide over the pipe - and then you can slide them into position over the joint.

Just remember to measure and mark the correct position on the pipe, clamp the pipe on either side and verify the socket's position before you weld.

Remember that two repair sockets are needed in order to replace the first welding socket. Always keep 4-6 in the box with extras and spares.

The products featured in this article are:

KP 2-63R: Single wall repair socket, also available in all other sizes.

KP 2-125/75SC-R: Anaconda repair socket - or order just the double wall reducers KP 29-125/75 separately.

KP C14-63: Mechanical transition fitting, also available in all other sizes. Use appropriate tools.